The Smipack SL55 Parts Manual is a comprehensive guide for understanding, maintaining, and repairing your packaging machine. It covers critical components, troubleshooting, and essential maintenance procedures, ensuring optimal performance and longevity.

1.1 Overview of the Smipack SL55 Packaging Machine

The Smipack SL55 is a heat-shrink packaging machine designed for efficient and reliable packaging solutions. Part of the S series, it offers manual and semi-automatic options, ideal for companies needing outputs up to 900 packs per hour. With a larger chamber and longer sealing blade than the SL45, the SL55 excels in packaging various products. Its user-friendly design and robust construction make it a versatile choice for businesses requiring consistent and high-quality packaging results.

1.2 Importance of the Parts Manual for Maintenance and Repair

The Smipack SL55 Parts Manual is crucial for effective maintenance and repair. It provides detailed information on machine components, enabling technicians to identify and replace parts efficiently. The manual ensures proper intervention on various parts, understanding maintenance operations, and troubleshooting common issues. By following the guide, users can extend the machine’s lifespan, prevent downtime, and maintain optimal performance. It serves as an essential resource for operators and maintenance personnel, ensuring the machine operates safely and efficiently at all times.

Key Components of the Smipack SL55

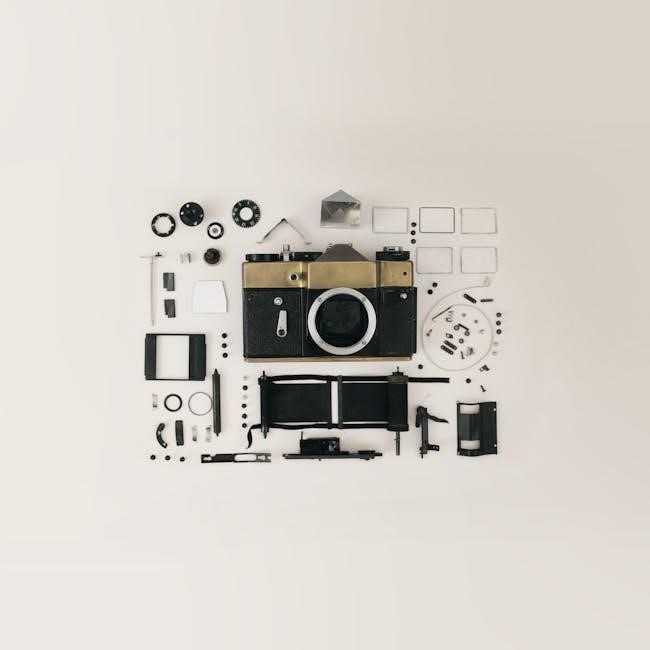

The Smipack SL55 features a robust design with a chamber-type shrink packaging system, a sealing blade, and essential structural components for efficient packaging operations and durability.

2.1 Identification of Critical Parts and Their Functions

The Smipack SL55 includes a chamber-type shrink packaging system, a sealing blade, and structural components. The chamber encloses products for uniform shrinkage, while the blade ensures precise film cutting. These parts work together to deliver efficient packaging results, maintaining durability and performance. Understanding their roles is crucial for effective operation and maintenance.

2.2 Exploring the Machine’s Structure and Design

The Smipack SL55 features a robust and modular design, optimized for efficient packaging operations. Its chamber-type system ensures uniform shrinkage, while the sealing blade provides precise film cutting. Structural components are built for durability, ensuring stability and alignment during use. The machine’s design allows easy access to critical parts, facilitating maintenance and upgrades. This layout enhances performance, making the SL55 a reliable choice for consistent and high-quality packaging results.

Understanding the Parts Manual Structure

The Smipack SL55 parts manual is structured for easy navigation, featuring detailed sections on components, maintenance, and troubleshooting. Its organized layout ensures quick access to essential information.

3.1 Navigating the Manual for Easy Reference

The Smipack SL55 parts manual is designed for easy navigation, featuring a clear table of contents and well-organized sections. Users can quickly locate specific parts, maintenance procedures, and troubleshooting guides. The manual’s structured format allows for seamless referencing, with detailed diagrams and descriptions to aid understanding. Whether you’re identifying components or resolving issues, the manual’s intuitive layout ensures efficient access to the information you need, making it an indispensable resource for operators and technicians.

3.2 How to Locate Specific Parts and Instructions

To locate specific parts and instructions in the Smipack SL55 manual, use the table of contents or index for quick navigation. Each section is clearly labeled, allowing users to find components by name or part number. Detailed diagrams and descriptions accompany each part, making identification straightforward. For instructions, refer to the relevant chapter or search by keyword. Cross-referencing ensures users can easily find associated maintenance or repair procedures, streamlining the process of resolving issues or replacing components efficiently.

Maintenance and Servicing Guidelines

Regular maintenance ensures optimal performance and longevity of the Smipack SL55. Follow routine tasks like cleaning, lubrication, and part inspections. Adhere to safety precautions to prevent accidents and ensure proper machine operation.

4.1 Routine Maintenance Tasks for Optimal Performance

Regular maintenance is crucial for the Smipack SL55’s efficiency. Clean and lubricate moving parts, inspect belts and seals for wear, and ensure all components are securely fastened. Check electrical connections and verify proper heating element function. Refer to the manual for specific guidelines and schedules. Perform these tasks during low-production periods to minimize downtime. Proper upkeep prevents unexpected breakdowns and ensures consistent packaging quality. Always follow safety protocols when servicing the machine.

4.2 Safety Precautions During Maintenance

Always disconnect power before performing maintenance to avoid electrical hazards. Wear protective gear, including gloves and safety glasses, when handling sharp or hot components. Never bypass safety features or interlocks, as this can lead to serious injury. Ensure proper ventilation when working with electrical or thermal elements. Use approved tools to prevent damage to parts or injury to yourself. Follow the manual’s guidelines for lockout/tagout procedures to ensure the machine is safely de-energized. Adhere to these precautions to prevent accidents and maintain a safe working environment.

Troubleshooting Common Issues

The Smipack SL55 parts manual provides detailed solutions for common problems, helping users identify symptoms and resolve issues efficiently with step-by-step guidance.

5.1 Identifying and Diagnosing Common Problems

The Smipack SL55 parts manual helps users identify and diagnose common issues, such as film jamming or uneven sealing, by providing detailed symptom descriptions and diagnostic steps; It guides technicians through troubleshooting processes, ensuring quick resolution of operational disruptions. The manual also highlights error codes and maintenance checks to prevent recurring problems, making it an indispensable tool for maintaining machine efficiency and performance.

5.2 Step-by-Step Solutions for Frequently Encountered Issues

The Smipack SL55 parts manual offers detailed, step-by-step solutions for common issues like film jamming, uneven sealing, and error codes. It provides clear repair guidance, including diagnostic checks and part replacements. For example, film jams are resolved by cleaning rollers and adjusting tension, while uneven sealing may require heating element calibration. The manual ensures technicians can address problems efficiently, minimizing downtime and ensuring consistent packaging quality. Diagrams and troubleshooting charts further simplify the repair process.

Upgrading and Customizing the Smipack SL55

The Smipack SL55 can be upgraded with compatible parts for enhanced performance and customized to meet specific packaging needs, ensuring optimal functionality and versatility in various applications.

6.1 Compatible Upgrades for Enhanced Performance

The Smipack SL55 supports various compatible upgrades to boost efficiency and adapt to specific packaging demands. Upgrading the chamber size or sealing blade can enhance performance for larger or complex packages. Additionally, advanced control systems and automation features can be integrated to streamline operations. These upgrades ensure the machine remains versatile and capable of meeting evolving production needs, while maintaining compatibility with original parts and specifications for seamless integration.

6.2 Customization Options to Meet Specific Needs

The Smipack SL55 offers customization options to tailor its performance to specific requirements. Users can modify the machine’s chamber size, sealing blade length, and control systems to suit different packaging needs. Additional features like adjustable temperature settings and customizable cycle times enhance flexibility. These options allow businesses to optimize the machine for particular products or production scales, ensuring efficient and precise packaging solutions without compromising on performance or reliability.

Downloading and Accessing the Manual

The Smipack SL55 parts manual is available as a PDF download, covering models SL44 to SL56. Select the file, enter the verification code, and access the guide easily.

7.1 How to Download the Smipack SL55 Parts Manual PDF

To download the Smipack SL55 parts manual, visit the official Smipack website or authorized portals. Select the SL55 model from the list, enter the required verification code, and click the download button. The PDF manual will be accessible, providing detailed parts information, maintenance guides, and troubleshooting tips. Ensure you download from trusted sources to avoid unauthorized or outdated versions. This guide is compatible with models SL44 to SL56, offering comprehensive support for your packaging machine needs.

7.2 Online Resources for the Manual and Related Guides

Access the Smipack SL55 parts manual and related guides through official Smipack websites or trusted platforms like vdocuments.site. Additional resources, such as instructional videos and user forums, are available on YouTube and specialized equipment websites. For model-specific guides, visit Boggsequipment.com or Smipack’s official support page. Ensure to verify the authenticity of sources to download accurate and up-to-date materials. These resources provide comprehensive support for maintenance, troubleshooting, and optimal machine operation.

Safety Guidelines for Operating the Smipack SL55

Ensure safe operation by wearing protective gear, following manual guidelines, and conducting regular inspections. Adhere to pre-operational checks to prevent accidents and maintain a secure working environment.

8.1 Essential Safety Measures to Prevent Accidents

Adhere to essential safety measures to prevent accidents while operating the Smipack SL55. Always wear protective gear, including gloves and safety glasses. Ensure loose clothing is tied back and avoid wearing jewelry that could get caught in moving parts. Conduct regular inspections of the machine and its surroundings. Follow the manual’s guidelines for safe operation and maintenance. Keep the work area clear of obstacles and ensure proper ventilation. Failure to follow these measures can result in injuries or equipment damage.

8.2 Pre-Operational Checks for Safe Machine Use

Before operating the Smipack SL55, perform thorough pre-operational checks to ensure safe and efficient use. Inspect all components, including the sealing blade, heating elements, and electrical connections, for proper function and security. Check for wear or damage on belts, wires, and moving parts. Verify that all guards are in place and functioning correctly. Ensure the machine is properly grounded and free from obstructions. These checks help prevent accidents and ensure optimal performance during operation.

Comparing Smipack SL55 with Other Models

The Smipack SL55 stands out with its larger chamber and longer sealing blade, making it ideal for higher output needs compared to the SL45 and other models.

9.1 Differences Between Smipack SL55 and SL45

The Smipack SL55 differs from the SL45 primarily in its larger chamber size and longer sealing blade, enabling higher output capacity. While the SL45 is suitable for smaller-scale operations, the SL55 is designed for more demanding applications, offering enhanced performance and versatility. Both models share similar operational principles but cater to different production needs, making the SL55 a preferred choice for businesses requiring increased efficiency and throughput.

9.2 Unique Features of the Smipack SL55

The Smipack SL55 stands out with its advanced chamber design and extended sealing blade, allowing for efficient packaging of larger products. Its robust construction ensures durability, while user-friendly controls simplify operation. The machine supports both individual and group packaging, making it versatile for various industries. Additionally, its compatibility with different film types, such as POE and PVC, enhances flexibility. These features position the SL55 as a reliable and adaptable solution for medium to high-volume packaging needs.

Technical Specifications of the Smipack SL55

The Smipack SL55 offers a packaging capacity of up to 300 packs per hour, designed for efficient performance in various industrial settings with precise engineering.

10.1 Detailed Specifications for Proper Machine Operation

The Smipack SL55 operates at up to 300 packs per hour, featuring a chamber size suitable for various packaging needs. It includes a robust sealing blade and durable construction, ensuring reliable performance. Designed for efficiency, the machine supports multiple film types, including POE and PVC, and is built with high-quality materials for long-term use. The control panel provides intuitive operation, making it user-friendly for industrial applications. These specifications ensure optimal functionality and adaptability in diverse packaging environments.

10.2 Understanding the Machine’s Output Capacity

The Smipack SL55 is designed to handle up to 300 packs per hour, making it ideal for medium-scale packaging needs. Its output capacity is influenced by package size, material type, and sealing requirements. The machine’s chamber size and blade length are optimized for efficient wrapping, ensuring consistent results. Understanding these factors helps maximize productivity and adapt to various packaging demands, making the SL55 a versatile choice for industrial and commercial applications.

Warranty and Support Information

The Smipack SL55 is backed by a comprehensive warranty covering parts and service. Contact Smipack support for assistance with repairs, maintenance, and technical inquiries.

11.1 Warranty Coverage for Parts and Service

The Smipack SL55 parts manual outlines the warranty coverage for both parts and service, ensuring protection for your investment. The warranty typically covers defects in materials and workmanship for a specified period.

Regular maintenance, as detailed in the manual, is essential to uphold warranty conditions. Contact Smipack support for specific terms and to initiate any warranty-related claims or service requests.

11.2 Contacting Smipack Support for Assistance

For any inquiries or issues with your Smipack SL55, contacting the support team is straightforward. Visit the official Smipack website to access contact details, including phone numbers, email addresses, and online support forms.

Ensure you have your machine’s model and serial number ready for efficient assistance. Smipack’s dedicated support team is available to address technical questions, warranty claims, and service requests, providing timely solutions to keep your operations running smoothly.

Common FAQs About the Smipack SL55

This section addresses frequently asked questions about the Smipack SL55, covering topics like maintenance, troubleshooting, and upgrades, providing quick solutions for common user inquiries.

12.1 Frequently Asked Questions by Users

Users often inquire about maintenance schedules, troubleshooting common issues, and locating specific parts. Questions include: “How do I access the parts manual?” “What are the steps to resolve machine downtime?” and “Can I upgrade my SL55 model?” Additional queries focus on understanding error codes, optimal packaging materials, and warranty coverage. These FAQs provide clarity on operational and technical aspects, ensuring smooth machine performance and addressing user concerns effectively.

12.2 Answers to Common Queries for Troubleshooting

Common queries include resolving error codes, addressing machine downtime, and repairing faulty components. The manual provides step-by-step solutions for issues like improper film alignment, heater malfunctions, and sensor errors; It also offers guidance on resetting the machine, replacing worn parts, and diagnosing electrical faults. Detailed repair procedures and troubleshooting checklists ensure users can quickly identify and resolve problems, minimizing operational disruptions and ensuring efficient machine performance.

Best Practices for Using the Smipack SL55

Regular maintenance, proper film alignment, and optimal temperature settings ensure efficient operation. Always follow safety guidelines and pre-operational checks to maximize machine lifespan and reliability.

13.1 Tips for Efficient and Safe Machine Operation

Adhere to the Smipack SL55 parts manual guidelines for optimal performance. Ensure proper film alignment and maintain optimal temperature settings. Conduct pre-operational checks and follow safety protocols to prevent accidents. Regularly inspect and clean the machine to avoid malfunctions. Use recommended materials and avoid overloading to extend lifespan. Train operators thoroughly and keep emergency stop buttons accessible. Schedule routine maintenance to ensure smooth operation and minimize downtime. These practices enhance efficiency, safety, and machine longevity.

13.2 Maximizing the Lifespan of Machine Components

To extend the lifespan of Smipack SL55 components, follow the parts manual’s maintenance guidelines. Regularly clean and lubricate moving parts to prevent wear. Avoid extreme temperatures and ensure proper film alignment to reduce stress on components. Schedule periodic inspections and replace worn parts promptly. Use genuine Smipack parts for reliability. Store spare components in a dry, cool environment to maintain quality. These practices ensure optimal performance and longevity of the machine’s critical elements.

Environmental Considerations

Adopt eco-friendly practices with the Smipack SL55 by minimizing material waste and using energy-efficient settings. Properly dispose of machine parts and packaging materials to reduce environmental impact.

14.1 Eco-Friendly Practices with the Smipack SL55

The Smipack SL55 supports eco-friendly practices by enabling efficient energy use and minimizing material waste. Proper disposal of parts and packaging materials reduces environmental impact. Using recyclable materials and optimizing settings further enhances sustainability. Regular maintenance ensures optimal performance, contributing to a greener workflow and extending machine lifespan.

14.2 Proper Disposal of Machine Parts and Materials

Proper disposal of Smipack SL55 parts and materials is crucial for environmental sustainability. Dispose of packaging films, worn parts, and non-recyclable materials responsibly. Check local regulations for hazardous waste disposal. Recycle metal and plastic components when possible. Ensure all fluids and chemicals are handled safely. Donate functional parts to reduce waste. Partner with certified recycling centers for eco-friendly disposal practices, minimizing the machine’s environmental footprint and promoting a sustainable workflow.

Resources for Further Learning

Access the Smipack SL55 parts manual online for detailed guides. Explore YouTube tutorials, official Smipack websites, and community forums for additional support and troubleshooting tips.

15.1 Recommended Reading and Guides for Advanced Users

For advanced users, the Smipack SL55 parts manual offers detailed technical specifications and maintenance guides. Additionally, explore the official Smipack website for PDF downloads and supplementary materials. YouTube tutorials provide hands-on demonstrations, while community forums share expert tips and troubleshooting solutions. These resources empower users to optimize machine performance and address complex issues effectively.

15.2 Online Communities and Forums for Smipack SL55 Users

Engage with online forums and communities dedicated to Smipack SL55 users for shared knowledge and support. Platforms like YouTube offer tutorials and troubleshooting tips, while specialized forums provide discussions on maintenance and customization. Websites such as vdocuments.site host downloadable manuals and guides. These resources foster collaboration and problem-solving among users, ensuring optimal machine performance and addressing specific needs effectively.

The Smipack SL55 Parts Manual is an invaluable resource for maintaining and optimizing your machine. It ensures efficient operation, troubleshooting, and longevity, making it essential for all users.

16.1 Summary of Key Points

The Smipack SL55 Parts Manual is a detailed guide for maintaining and repairing your packaging machine. It covers critical components, troubleshooting, and essential maintenance procedures. The manual is designed for operators and technicians, providing clear instructions for optimal performance. It includes sections on machine structure, safety guidelines, and customization options. By following the manual, users can ensure longevity and efficiency of the Smipack SL55, making it an indispensable resource for proper machine operation and upkeep.

16.2 Final Thoughts on Using the Smipack SL55 Parts Manual

The Smipack SL55 Parts Manual is an essential resource for ensuring optimal performance and longevity of your packaging machine. It provides detailed guidance for maintenance, repairs, and troubleshooting, empowering users to handle the machine with confidence. By following the manual, operators and technicians can maximize efficiency, safety, and productivity. This comprehensive guide is a vital tool for anyone involved in the operation or upkeep of the Smipack SL55, making it an indispensable asset for achieving professional results.